Our Process

The Turbid water treatment process is a complete end-to-end water treatment solution.

Our team of environmental scientists and engineers provide tailor-made water treatment solutions.

Test

Testing soil and water ensures efficiency in design and treatment of the water from a particular site.

Design

Using the soil and water test, a specific treatment system design will be created for your site ensuring the most efficient and practical design is implemented.

Build

Build independently or assist a third-party contractor to ensure the highest quality product is delivered.

Install

Trained personnel will install your treatment solution equipment ready for operation.

Service

Ensures the system is operationally sound and product supply levels are adequate until the next visitation.

Report

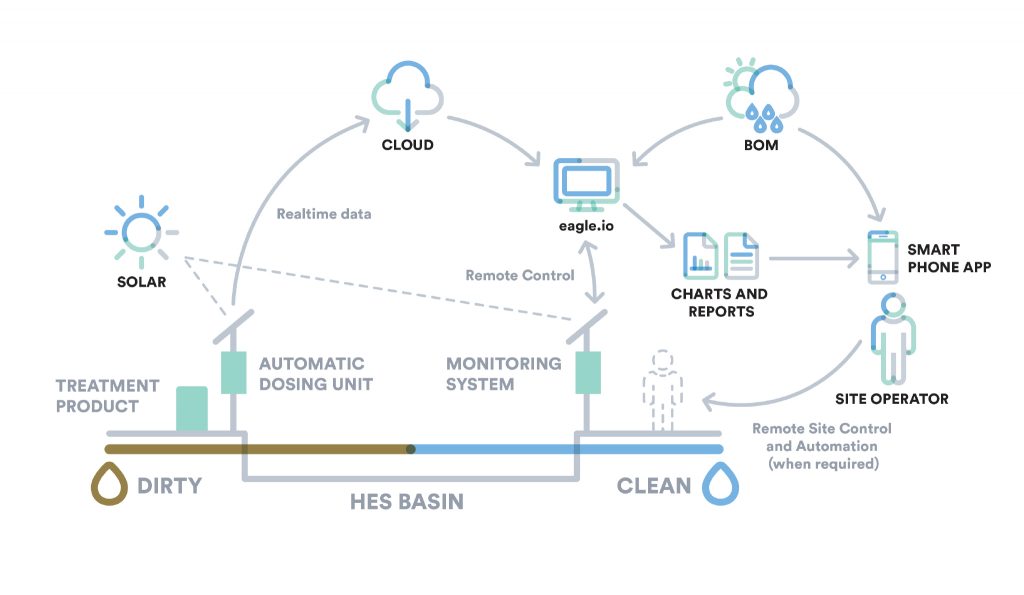

Monitoring can be implemented to ensure the system is achieving goals and the data collected is logged and available for real-time analysis.

Set your sediment control to auto-pilot

Turbid’s Stormwater Process means you can set your on-site sediment control to auto-pilot.

Turbid Water Solutions provide the complete stormwater solutions with innovative designs, treatment and monitoring processes to ensure only clean water is leaving your site without hassle or restraints to your operations.

Get to know High Efficiency Sediment basins

Turbid are leading the industry with the use of HES basins. These types of basins can:

- Significantly reduce the footprint (up to one fifth) of sediment controls for both temporary and longer termed construction activities.

- Improve environmental performance.

- Significantly reduce the frequency of turbid discharges off-site resulting in less complaints and less risk of enforcement from regulators.

- Provides a source of construction water.

- Reduce manual handling requirements resulting inlower costs for flocculation of basins and improved WH&S.

- When considered early as part of an integrated stormwater management approach it can minimise land take for permanent stormwater controls.

- Manage construction phase sediment loading risks to WSUD assets, thereby allowing WSUD assets to be constructed earlier, potentially saving time and money for developers.

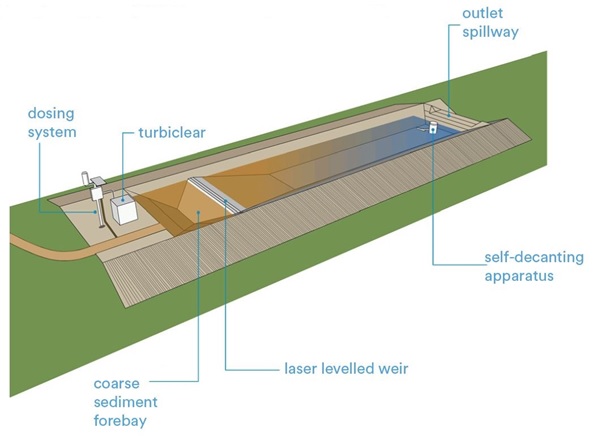

How HES basins work

High Efficiency Sediment (HES) basins work on a continuous-flow basis rather than the batch process that traditional sediment basins operate by. This means that treatment and discharge occur throughout a rainfall event rather than at the end of an event. This continuous-flow approach offers many advantages, the main one being that a much greater volume of runoff can be treated for a given basin size, compared to traditional batch basins.

Key Components

DOSING SYSTEM:

An automated system is provided at the start of the basin to deliver a dose of treatment product to enhance the settlement of fine and dispersive sediment. The dosing system can be either triggered by rainfall or can be based on the incoming flow rate.

COARSE SEDIMENT FOREBAY:

This is the first cell of the basin and is where the majority of mixing of the treatment product with run off occurs and is also where the majority of the coarse sediment is deposited.

LEVEL-SPREADER/WEIR:

The level-spreader acts to distribute the flow across the full width of the basin so that velocities are minimised and settling is enhanced.

SETTLING ZONE:

This second cell of the basin is where settling of fine and dispersive sediment occurs. The fine particle size and slow settling velocities require this cell to be large so that non-turbulent settling can occur.

OUTLET STRUCTURES:

There are two different types of HES basins specified in IECA (2016 Addendum) – Type A and Type B. The main difference between these types is the outlet structure. Type A basins have a floating-decant as the primary outlet which ‘skims’ water from the top of the water column and allows the basin to be largely emptied between events. Type B has only a spillway outlet and remains full following an event.

Site soil and water testing (jar test)

Site water testing

Floc Box dosing unit (installation)

ifod-FLOW dosing unit (installation)

ifod-PUMP dosing unit (installation)

HES basin with Floc Box doser (build and install)

HES basin with Floc Box doser (build and install)

HES basin with Floc Box doser (operating)

HES basin with ifod-FLOW doser (operating)

HES basin with ifod-FLOW doser (operating)

HES basin decant system (operating)

HES basin (water testing)