COMPLYING WITH THE SPP –

TECHNICAL NOTE FOR LOCAL GOVERNMENT & ESC PRACTITIONERS

- REASONS FOR THE NEW DESIGN OBJECTIVE

- DEMONSTRATING COMPLIANCE

- ADDITIONAL BENEFITS OF HIGH EFFICENCY SEDIMENT BASINS

- STANDARD DEEMED TO COMPLY SOLUTION FOR SMALL SITES (<2Ha)

1.0 INTRODUCTION

The State Planning Policy 2017 (DILGP, 2017) came into effect on the 3rd July 2017and introduces a new stormwater management design objective for sediment control on construction sites.

New Operational Works applications which are for urban purposes and which involve disturbing a land area of 2500m2 or greater in size must comply with the new design objective.

One recognised method for achieving compliance with this design objective is to implement High Efficiency Sediment Basins (HES basins).

The purpose of this Technical Note is to assist Local Government and Industry by explaining the reason for the new design objective and to provide tools to help implement the change.

All exposed areas greater than 2500 m2 must be provided with sediment controls which are designed, implemented and maintained to a standard which would achieve at least 80% of the average annual runoff volume of the contributing catchment treated (i.e. 80% hydrologic effectiveness) to 50mg/L Total Suspended Solids (TSS) or less, and pH in the range (6.5–8.5)

(Appendix 2, Table A)

2. REASONS FOR THE NEW DESIGN OBJECTIVE

Prior to the release of the SPP 2017, sediment basins (termed henceforth as ‘traditional basins’) operated as batch systems. These systems were designed to capture a specific volume of runoff from the design rainfall event. The design rainfall event was typically the 5-day 80th percentile rainfall depth (mm).

Traditional basins work by having the storage empty prior to the rainfall event. Runoff during the event fills the basin and any excess runoff passes over the basin spillway untreated. Following the event, the captured water is treated (often with a chemical flocculant/coagulant). Once the discharge standard is achieved for the water in the basin (50mg/L TSS), the basin is emptied in readiness for the next rainfall event.

This process is illustrated in Figure 1.

Figure 1 – Steps in Traditional batch sediment basin operation

Basin empty prior to rainfall

Once the event is complete, captured water is treated to discharge standard (50mg/L TSS)

Runoff fills basin. Once full, excess runoff is discharged over basin spillway

Basin is emptied in readiness for next rainfall event

2.1 TRADITIONAL SEDIMENT BASINS

For many years, ESC practitioners in Queensland had observed that these traditional sediment basins overtopped frequently during the wet season, and people began to question how effective these traditional basins were at capturing fine and dispersive sediment and hence at protecting downstream water quality. The previous design standard (to capture the 5-day 80th percentile rainfall depth) was very abstract and provided no insight into the actual effectiveness of traditional basins.

Studies were undertaken to try and provide a more meaningful measure of the effectiveness of tradition sediment basins. These studies used the term ‘hydrologic effectiveness’ to report basin performance, which is simply the percentage of total runoff which is able to be treated to the discharge standard by the basin. By undertaking simulation using long-term (10 years) of rainfall data, estimates of hydrologic effectiveness were able to be obtained and demonstrated that traditional sediment basins operated in coastal regions of Queensland were largely ineffective (Rowlands and Leinster, 2015; Robson, 2015).

Table 1 provides estimates of hydrologic effectiveness for traditional sediment basins at various locations in Queensland, along with the previous design standard (5-day 80th percentile rainfall depth).

Table 1 Performance estimates for Traditional batch sediment basins

| Location | 5-Day 80th %ile Rainfall Depth (mm) | Hydrologic Effectiveness | 5-day 85th %ile Rainfall depth (mm) | Hydrologic Effectiveness |

| Weipa | 35.8 | 11% | 46.2 | 14% |

| Cairns | 56.2 | 20% | 74.1 | 26% |

| Townsville | 43.8 | 22% | 57.1 | 26% |

| Mackay | 43.8 | 27% | 57.1 | 31% |

| Caloundra | 40.6 | 34% | 52.7 | 41% |

| Sydney | 29.7 | 38% | 38.8 | 44% |

| Canberra | 20.4 | 60% | 25.1 | 68% |

| Melbourne | 20.6 | 65% | 25.4 | 71% |

It can be seen from Table 1 that the performance of sediment basins decreases as you move further North. In Caloundra only 34% of the average annual runoff is able to be treated (meaning 66% of runoff goes untreated). This poor result is further eroded as you move into the tropics, with Weipa the worst-performing location with only 11% of average annual runoff being able to be treated. There is little improvement in performance by increasing the design rainfall depth from the 80th %ile to the 85th %ile.

This highlights the shortfalls of traditional sediment basins and the previous design standard. The reason traditional basins are so ineffective in coastal Queensland is because rainfall in Queensland often occurs in consecutive events which do not allow sufficient time for the batch process which traditional basins employ to be completed.

The new design objective in the SPP 2017 recognises the inherent unsuitability of traditional batch basins for Queensland and mandates a significant shift in performance. Instead of treating 11-34% of site runoff, developments are now required to achieve treatment of 80% of the average annual runoff volume.

3. DEMONSTRATING COMPLIANCE

The Queensland State Government engaged with IECA to produce a design guideline for High Efficiency Sediment Basins as a way of assisting Industry to meet the new design objective (IECA, 2016 Addendum). The design guideline is freely available from the IECA website.

Due to it being a national document, the IECA guideline does not mention the SPP 2017 design objective and the design procedures in the document were not developed specifically to meet the SPP 2017 Design Objective. However long-term rainfall simulation has been undertaken of basins designed following the IECA (2016 Addendum) procedures and it has been confirmed that the 80% hydrologic effectiveness objective can be achieved.

However, the IECA guideline is complex and can be challenging to follow. A range of tools have therefore been developed by Turbid to aide practitioners with the aim of making the HES technology more accessible and easier to implement. These can be downloaded from the Turbid website.

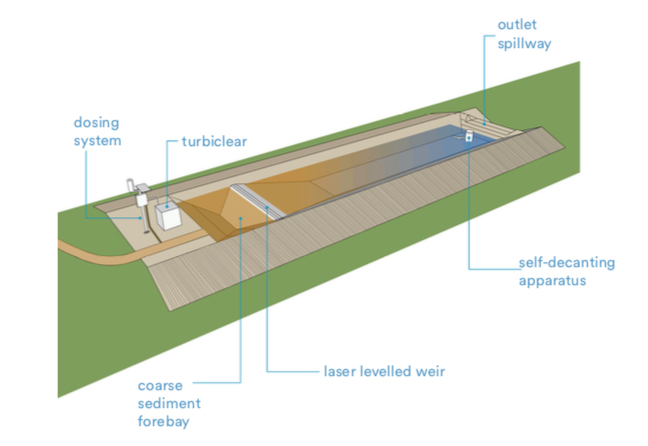

3.1 HOW HES BASINS WORK

High Efficiency Sediment (HES) basins work on a continuous-flow basis rather than the batch process that traditional sediment basins operate by. This means that treatment and discharge occur throughout a rainfall event rather than at the end of an event. This continuous-flow approach offers many advantages; the main one being that a much greater volume of runoff can be treated for a given basin size, compared to traditional batch basins.

KEY COMPONENTS:

DOSING SYSTEM

An automated system is provided at the start of the basin to deliver a dose of chemical coagulant to enhance the settlement of fine and dispersive sediment. The dosing system can be either triggered by rainfall or can be based on incoming flowrate

COARSE SEDIMENT FOREBAY:

This is the first cell of the basin and is where the majority of mixing of the coagulant with runoff occurs and is also where the majority of coarse sediment is deposited

LEVEL-SPREADER/WEIR:

The level-spreader acts to distribute the flow across the full width of the basin so that velocities are minimised and settling is enhanced.

SETTLING ZONE

This second cell of the basin is where settling of fine and dispersive sediment occurs. The fine particle size and slow settling velocities require this cell to be large so that non-turbulent settling can occur

OUTLET STRUCTURES

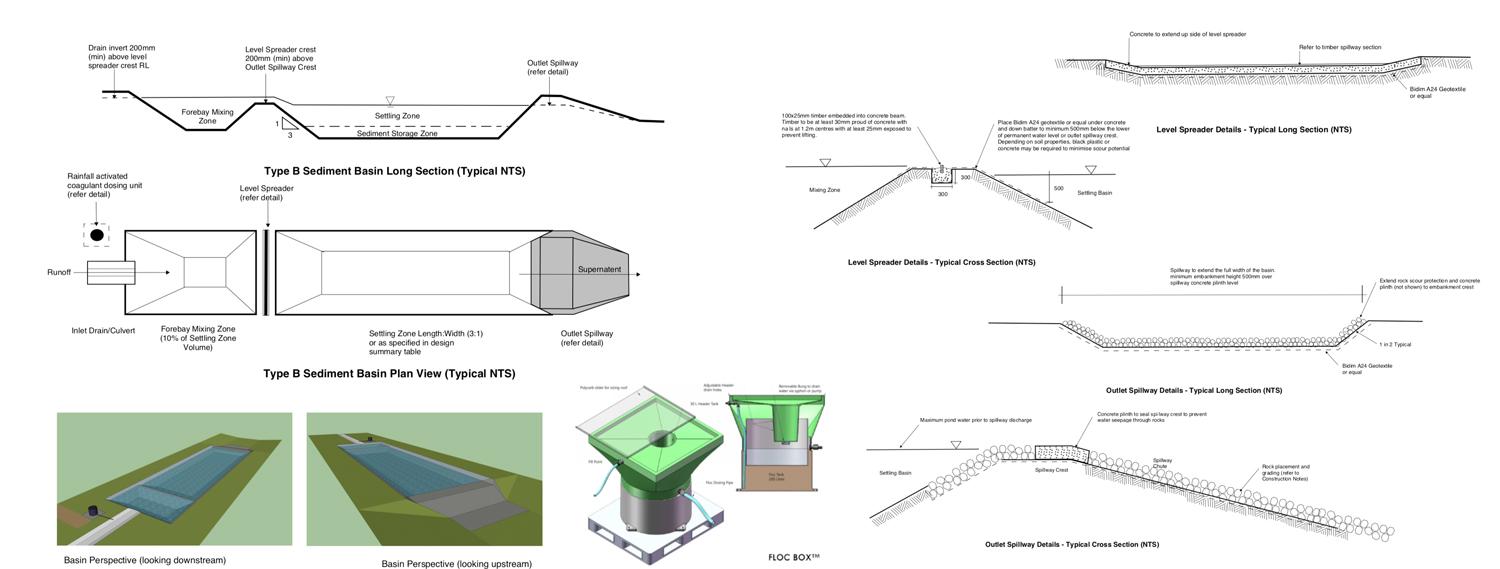

There are two different types of HES basins specified in IECA (2016 Addendum) – Type A and Type B. The main difference between these types is the outlet structure. Type A basins have a floating-decant as the primary outlet which ‘skims’ water from the top of the water column and allows the basin to be largely emptied between events. Type B has only a spillway outlet and remains full following an event.

3.2 TYPE A AND TYBE B HES BASINS

The full design procedures for Type-A and Type-B HES basins are provided in IECA (2016 Addendum). TURBID have developed a design tool to aide the design of HES basins and is based on the IECA (2016 Addendum) procedures. The TURBID design tool is available to download from the Turbid website.

The following points should be noted when following the IECA (2016 Addendum) procedures and using the TURBID design tool:

TYPE-A HES:

• IECA (2016 Addendum) limits the low-flow decant rate to 9L/s/ha. This rate is well below optimum for high rainfall-intensity locations and will result in excessive basin size (e.g. Cairns, Mackay). It is recommended that specialist advice be sought from TURBID if designing Type-A HES basins in these locations

TYPE B HES:

- The use of an effective and fast-acting coagulant is critical for the success of both Type-A and Type-B HES basins. The design settling rate (laboratory settling rate) must be set at no more than 0.6m/hr. This is to provide a degree of safety in the sizing of the settling zone volume. The coagulant selected to be actually used in the basin is to meet or exceed this design settling rate.

- The scour velocity checks (steps 5B, 6B in IECA, 2016 Addendum) are to be undertaken as informative only. If resuspension through scour is identified as a potential issue, then this is best addressed through monitoring basin performance and retrofitting permeable baffles if resuspension is observed.

- Type B basins should only be provided for a maximum catchment area of 5Ha or a design treatment flowrate of 250L/s. Where greater catchment areas are involved, consideration should be given to implementing a number of distributed systems or implementing an alternative arrangement where flow into the

settling zone can be regulated to below 250L/s. If neither of these options is available, then specialist advice should be sought from TURBID on dosing and flow management.

3.3 INITIAL ESTIMATES OF SETTLING VOLUME

TURBID have undertaken design calculations for a number of locations in Queensland in order to provide initial estimates of settling volume. These estimates are provided in Table 2.

These initial estimates can be used for early planning purposes or may also be accepted by Local Governments as ‘deemed-to-comply’ solutions for smaller scale developments up to 2ha. Practitioners are advised to check with the relevant Council.

Table 2 Initial Estimates of Settling Volume for HES Basins

| Location | Type A Settling Volume (m3/ha) | Type B Settling Volume (m3/ha) |

| Ipswich | 140 | 270 |

| Toowoomba | 110 | 260 |

| Gold Coast (Southport) | 350 | 330 |

| Brisbane | 200 | 310 |

| Redcliffe | 250 | 330 |

| Sunshine Coast | 340 | 350 |

| Bundaberg | 260 | 400 |

| Gladstone | 230 | 320 |

| Rockhampton | 200 | 330 |

| Mackay | 430 | 360 |

| Townsville | 330 | 310 |

| Cairns | 660 | 360 |

3.4 DEEMED-TO-COMPLY SOLUTION

If used as a deemed-to-comply solution, it is recommended that only Type-B is adopted, as there is little variation in settling zone volume throughout the State (as per Table 2) and the implementation of these basins is less complex than Type-A.

The following parameters should also be adopted for deemed to comply solutions:

a) Provide basin settling volume sized as per Table 2

b) Average settling zone depth of 1-2m

c) Sediment storage volume sized as 30% of settling volume

d) Length-width ratio 3:1

e) spillway design as per IECA (2016 Addendum) or conservatively set to full basin width and with 500mmfreeboard to basin embankment

f) forebay sized as 10% of the settling zone volume and with flow-distribution weir (level-spreader) set 100-200mm above outflow spillway level

g) Provide rainfall-activated flocculant/coagulant dosing system on the single inflow point to the basin forebay. The dosing system is to be re-supplied with flocculant/coagulant after each rain event, or as required based on the coagulant storage capacity of the selected dosing unit, to ensure subsequent events will be treated.

h) Select and supply a flocculant/coagulant determined through jar test conducted as per IECA (2016 addendum) Section B3 which achieves a minimum settlement clarity of 150mm within 15 minutes

A standard drawing showing the above suggested deemed-to-comply solution for small catchments (<2ha) is provided in Appendix A.

4. ADDITIONAL BENEFITS OF HIGH EFFICIENCY SEDIMENT BASINS

The potential for significantly improved environmental outcomes from HES basins is clear. There are also a range of other benefits to be gained from implementing this technology, which include:

REDUCED LABOUR COSTS AND IMPROVED WH&S:

With traditional sediment basins, coagulant dosing and dewatering operations are done manually. This is often a time-consuming process requiring significant upskilling of the workforce and requiring workers to be present on site during inclement weather. The use of HES systems with auto-dosers removes the need for specialist skills in the contractor workforce and also eliminates direct handling of chemicals and the need for staff to be present during rainfall events.

SOURCE OF CONSTRUCTION WATER:

Type-B HES basins do not need to be emptied like tradition basins and remain full following a rainfall event. This stored water can be used for construction-purposes and provides a valuable water source for many sites.

LOWER COMPLIANCE RISK:

With traditional basins, turbid water would be expected to be discharged from the site on average between 89-66% of the time (depending on location). This means that it is more than likely that if a regulator were to visit a site with a traditional basin during an event, there would be turbid water being discharged. When this occurs, it is very difficult for the developer to demonstrate that all things reasonable and practicable have been done to prevent or minimise the release. The use of HES basins means that turbid water would only be expected to be discharged less than 20% of the time on average, meaning the risk of further investigation by regulators is significantly reduced.

REFERENCE LIST

- Department of Infrastructure, Local Government and Planning. (2017). State Planning Policy 2017

- International Erosion Control Association. (2008). Best Practice Erosion and Sediment Control

- International Erosion Control Association. (2016 Addendum). Appendix B – Sediment basin design and operation (draft)

- Robson., K. (2015) An assessment of the performance of current best practice sediment basins vs. high efficiency sediment basins based on modelling and field studies. Stormwater Queensland Conference. Toowoomba

- Rowlands., L. and Leinster., S. (2015) Sediment basin performance – is it as good as you think and does it really matter? Stormwater Queensland Conference. Toowoomba

IMPORTANT NOTE

This Technical Note and all its components (including images, audio, video, text) is copyright. Apart from fair dealing for the purposes of private study, research, criticism or review as permitted under the Copyright Act 1968, no part may be reproduced, copied, transmitted in any form or by any means (electronic, mechanical or graphic) without the prior written permission of Turbid.

Turbid waives all liability to any third party loss, damage, liability or claim arising out of or incidental to a third party publishing, using or relying on the facts, content, opinions or subject matter contained in this Technical Note.

APPENDIX A

TYPE B DEEMED TO COMPLY

Standard Type B High Efficiency Sediment Basin for Small Catchments (<2ha)

Notes

Auto Doser

1. Provided as either Floc Box or iFOD-Rain to manufacturers specification. Floc Box unit sizing to be in accordance with the table below.

| Area Treated (HA) | Floc Box Unit (Litres) |

| <1 | 75 |

| <2 | 200 |

2. Doser and supply of flocculant to be provided on level pad 4mx4m within 10m of dosing point.

3. All-weather access track to be provided to doser.

4. Flocculant provided as Turbiclear (ACH). If alternative flocculant used then the basin size is to be increased according to jar settlement test (refer to table below.

| Jar Settlement after 15 min (mm) | Multiplication Factor to Settling Zone Volume |

| 50 | x3 |

| 75 | x2 |

| 100 | x1.5 |

| 150 | x1 |

Basin construction: Materials

5. Earth Fill: clean soil with Emerson Class 2(1), 3, 4 or 5 and free of roots, woody vegetation, rocks and other unsuitable material. Soil with Emerson Class 4 and 5 may not be suitable depending on particle size distribution and degree of dispersion. Class 2(1) should only be used upon recommendation from geotechnical specialist.

6. Spillway rock: hard, angular, durable, weather resistant and evenly graded rock with 50% by weight larger than the specified nominal (d50) rock size. Large rock should dominate, with sufficient small rock to fill the voids between larger rock. the diameter of the largest rock should be no larger than 1.5 times the nominal rock size. The specific gravity should be at least 2.5.

7. Geotextile fabric: heavy duty, needle-punched, non-woven cloth, minimum ‘bidim’ A24 or equivalent.

Construction

8. Notwithstanding any description contained with approved plans or specifications, the Contractor shall be responsible for satisfying themselves as to the nature and extent of the specified works and the physical and legal conditions under which the works will be carried out. This shall include means of access, extent of clearing, nature of the materials to be excavated, type and size of mechanical plant required, location and suitability of water supply for construction and testing purposes, and any other likely matters affecting the construction of the works.

9. Refer to approved plans for location, dimensions, and construction details. If there are questions or problems with the location, dimensions, or method of installation, contact the engineer or responsible on-site officer for assistance.

10. Before starting any clearing or construction, ensure all the necessary materials and components are on the site to avoid delays in completing the sediment basin once works begin.

11. Install requires short term sediment control measures downstream of the proposed earthworks to control sediment runoff during construction of the basin.

12. The area to be covered by the embankment, borrow pits and incidental works, together with an area extending beyond the limits of each for a distance not exceeding five (5) metres all around must be cleared of all trees, scrub, stumps, roots, dead timber and rubbish and disposed of in a suitable manner. Delay clearing the main basin area until the embankment is complete.

13. Ensure all holes made by grubbing within the embankment footprint are filled with sound material, adequately compacted, and finished flush with the natural surface.

Cut-off Trench

14. Before construction of the cut-off trench or any ancillary works within the embankment footprint, all grass growth and topsoil must be removed from the area to be occupied by the embankment and must be deposited clear of this area and reserved for topdressing the completed embankment.

15. Excavate a cut-off trench along the centre line of the earth fill embankment. Cut the trench to stable soil material, but in no case make it less than 600mm deep. the cut-off trench must extend into both abutments to at least the elevation of the outlet spillway crest. Make the minimum bottom width wide enough to permit operation of the excavation and compaction equipment, but in no case less than 600mm. Make the side slopes of the trench no steeper than 1:1 (H:V).

16. Ensure all water, loose soil, and rock are removed from the trench before backfilling commences. The cut-off trench must be backfilled with select earth-fill of the type specified for the embankment, and this soil must have a moisture content and degree of compaction the same as specified for the core zone.

17. Material excavated from the cut-off trench may be used in the construction of the embankment provided it is suitable and it is placed in the correct zone according to its classification.

Embankment

18. Scarify areas on which fill is to be placed before placing the fill.

19. Ensure all fill material used to form the embankment meets the specifications certified by a soil scientist of geotechnical specialist.

20. The fill material must contain sufficient moisture so it can be formed by hand into a ball without crumbling. If water can be squeezed out of the ball, it is too wet for proper compaction. Place fill material in 150 to 200mm continuous layers over the entire length of the fill area and then compact before placement of further fill.

21. Unless specified on the approved plans, compact the soil at about 1% to 2% wet optimum and to 95% modified or 100% standard compaction.embankment to an elevation 10%higher than the design height to allow for settling

22. Where both dispersive and non-dispersive classified earth-fill materials are available, non-dispersive earth-fill must be used in the core zone. the remaining classified earth-fill materials must only be used as directed by the site superintendent.

23. Where specified, construct the embankment to an elevation 10% higher than the design height to allow for settling; otherwise finished dimensions of the embankment after spreading of topsoil must conform to the drawing with a tolerance of 75mm from specified dimensions.

24. Ensure debris and other unsuitable building waste is not placed within the earth embankment.

25. After completion of the embankment all loose uncompacted earth-fill material on the upstream and downstream batter must be removed prior to spreading topsoil.

26. Topsoil and re-vegetate/stabilise all exposed earth as directed within the approved plans.

Spillway Construction

27. The spillway must be excavated as shown on the plans, and the excavated material if classified as suitable, must be used in the embankment, and if not suitable it must be disposed of into spoil heaps.

28. Ensure excavated dimensions allow adequate boxing-out such that the specified elevations, grades, chute width, and entrance and exit slopes for the emergency spillway will be achieved after placement of the rock or other scour protection measures as specified in the plans.

29. Place specified scour protection measures on the emergency spillway. Ensure the finished grade blends with the surrounding area to allow a smooth flow transition from spillway to downstream channel.

30. If a synthetic filter fabric underlay is specified, place the fabric directly on the prepared foundation. If more than 1 sheet of filter fabric is required, overlap the edges by at least 300mm and place anchor pins at minimum 1m spacing along the overlap. bury the upstream end of the filter fabric a minimum 300mm below ground and where necessary, bury the lower end of the fabric or overlap a minimum 300mm over the next downstream section as required. Ensure the filter fabric extends at least 1000mm upstream of the spillway crest.

31. Take care not to damage the fabric during or after placement. If damage occurs, remove the rock and repair the sheet by adding another layer of fabric with a minimum overlap of 300mm around the damaged area.3If extensive damage is suspected, remove and replace the entire sheet.

Download Technical Note PDF

IMPORTANT NOTE

This Technical Note and all its components (including images, audio, video, text) is copyright. Apart from fair dealing for the purposes of private study, research, criticism or review as permitted under the Copyright Act 1968, no part may be reproduced, copied, transmitted in any form or by any means (electronic, mechanical or graphic) without the prior written permission of Turbid.

Turbid waives all liability to any third party loss, damage, liability or claim arising out of or incidental to a third party publishing, using or relying on the facts, content, opinions or subject matter contained in this Technical Note.